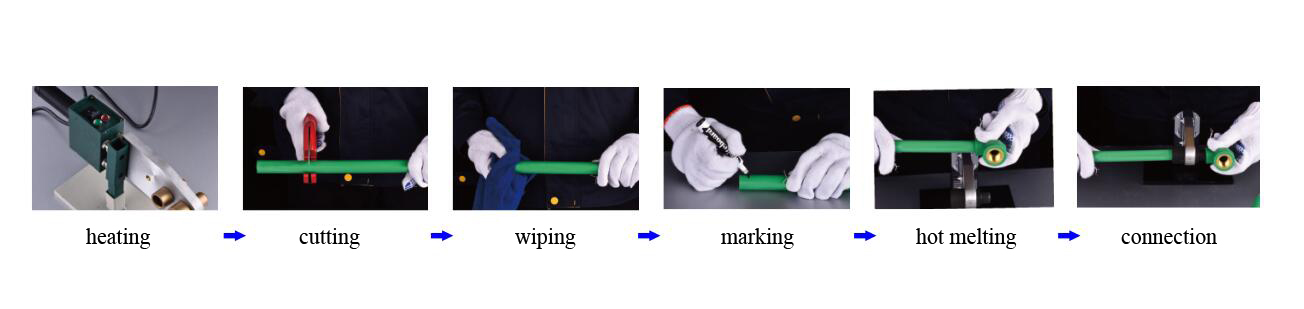

A. The hot-melt machine can be used after the power is turned on and the indicator light is on when it reaches the working temperature (260℃±10℃);

B. The end of the pipe should be removed by 40~50mm before installation. When cutting the pipe, the end part should be perpendicular to the axis of the pipe. Pipe shears or pipe cutters should be used to cut pipes, and hacksaws can also be used. The end part of the pipe after cutting should be free of burrs;

C. According to the construction drawings or the actual situation of the site, measure the pipe and cut the appropriate length and prepare the pipe fittings;

D. At the connecting end of the pipe&fitting, the pipe should be at least 50mm, and the entire socket of thefitting should be clean, dry and oil-free;

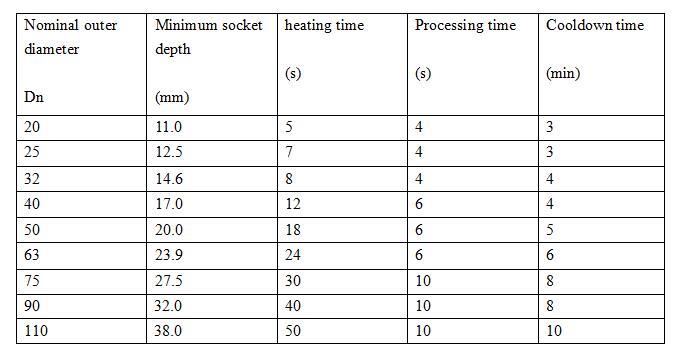

E. Use a caliper and a pen to measure and plot the insert depth at the pipe end, and the insert depth should not be less than the requirements in the table below;

Note: This table applies to an ambient temperature of 20°C. Below the ambient temperature, the heating time should be appropriately extended; if the ambient temperature is lower than 5°C, the heating time should be extended by 50%.

F. The heating time, processing time and cooling time are recommended according to the requirements in the table above.

G. When welding elbows or tees, according to the requirements of the design drawings, should pay attention on its direction, and the position,,position on the straight line of the pipe should be marked with auxiliary signs;

H. During installation, guide the pipe end into the heating jacket without rotation, and insert it to the marked depth. At the same time, push the pipe fitting onto the heating head without rotation, and push it to the socket end face of the pipe fitting and the flange end face of the hot melt head.

I. After the heating time is reached, immediately remove the pipe and fitting from the heating jacket and the heating head at the same time, and insert them to the marked depth in a straight line and evenly without rotation, so that a uniform flange is formed at the joint;

J. Within the specified heating time, the newly welded joint can still be corrected, but must not be rotated.

hot melt connection steps